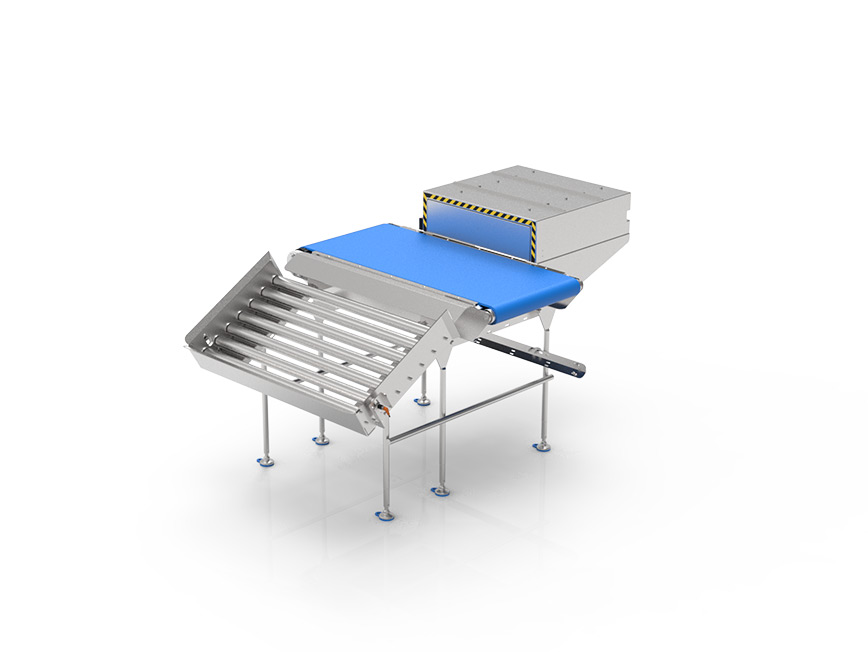

Reject conveyor

The Halpaq reject conveyor automatically removes non-compliant bags, whether they are underweight or contaminated with metal. It ensures a continuous and secure production flow thanks to its robust, enclosed and hygienic design, suitable for industrial and food environments.

Meticulous bag sorting

The Halpaq rejection conveyor automatically handles defective bags detected on bagging lines, whether due to weight discrepancies or metal contaminants. It rejects one or more bags without interrupting the production rate, while maintaining a high level of operator safety thanks to its closed design that complies with industry standards.

Its robust construction in painted steel or 304/316 stainless steel guarantees optimum resistance to demanding environments. The system uses an eco-efficient motor to limit energy consumption and offers accumulation options for storing several defective bags. Its EHEDG hygienic design facilitates cleaning, reduces downtime and ensures compliance with strict food standards.

Easy to integrate, it connects directly to checkweighers, metal detectors or other Halpaq equipment to form a complete quality control chain. Maintenance is reduced thanks to a simple, reliable and durable design.

Key benefits

- 01. Automatic and precise ejection of non-compliant bags.

- 02. Closed design ensuring operator safety and protection.

- 03. Compatible with painted steel or 304/316 stainless steel.

- 04. Continuous flow without line interruption.

- 05. Accumulation options for multiple rejects.

- 06. Hygiene ensured via EHEDG design.

- 07. Low energy consumption.

- 08. Easy adaptation to new or existing lines.

Ready to discuss your industrial needs?

Our technical team understands the specific challenges of each sector.

Let us help you find the ideal bagging solution for your application.