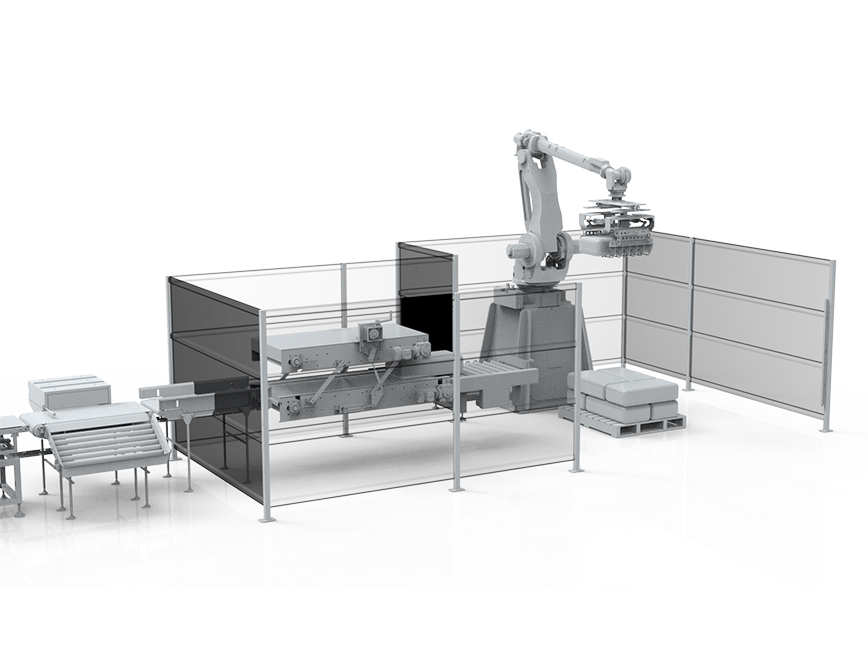

Robotic bag palletiser

PAL 600

The HALPAQ – PAL 600 robotic palletiser handles bags or boxes with great precision. Ideal for medium to high production lines, it fits easily into the most confined work areas.

Performance, Versatility and Compactness

The PAL 600 robotic palletiser is the ideal solution for companies looking for a fast, accurate machine that can adapt to different product formats: bags, cartons, packages and trays.

It combines compactness, robustness and exceptional speed, making it a major asset for medium to very high production lines.

Thanks to its optimised design and full integration of Halpaq peripherals, this palletiser ensures perfectly stable, consistent palletising tailored to each customer’s specific needs.

The benefits for your business

- 01.Reduced labour costs thanks to the robot’s speed and complete automation.

- 02.Consistent palletising quality with enhanced layer stability and pallet uniformity.

- 03.Maximum flexibility for rapid adaptation to changes in formats, product types or speeds.

- 04. Enhanced safety thanks to a design that protects operators and ensures continuous production.

- 05.Simple integration: its compact size and intuitive software allow for quick implementation in almost any industrial environment.

Key features

Speed and efficiency

4-axis architecture optimised for repetitive and rhythmic movements.

Compact and versatile

Compact design allowing integration even in restricted work areas.

Total adaptability

Quick and easy format changes thanks to intuitive management software.

Modular

Capable of handling all types of pallets. Production of all types of layers, simple or complex.

Intuitive interface

Touchscreen operator panel for quick and easy control.

Technical specifications

Robotic bag palletiser PAL 600

| Beach bags handled | 5 to 50 kg |

| Production rate | Up to 600 bags/hour |

| Pallet height | Up to 1800 mm |

| Standard pallet formats | Euro, 1000×1200, 1200×1200 |

| Safety enclosure | Fenced + secure access |

| Operator interface | 15.6" HMI touchscreen with programmable recipes |

| Compressed air supply | 4 bar |

| Power supply | 400 V – 50/60 Hz |

Custom engineering solutions

Our engineering team can customise every aspect of the system to meet your unique requirements: from bespoke parts to complete systems for your specific processes.

- Heavy-duty roller conveyor

Motorized conveyor designed for transporting and accumulating pallets at the palletizer outlet. - Pallet Dispenser

Loaded with stacks of pallets, it feeds the line with individual pallets as needed. - Sheet Dispenser

Automatic system for placing cardboard or PE film sheets on pallets to insulate the bags from the wood or nails of the pallet. - Interlayer placement

System that positions interlayer sheets between layers, ensuring better bag stability. - Layer compression system

Device combining lateral and top compression to ensure compact and perfectly stable pallets. - MES and ERP connection

Interface for connecting the palletizer controller to production management and customer traceability systems. - Automatic stretch wrapping machine

Downstream equipment that protects pallets with stretch wrap. - Automatic strapping machine

Final packaging system that secures the pallet with strapping.

Ready to discuss your industrial needs?

Our technical team understands the specific challenges of each sector.

Let us help you find the ideal bagging solution for your application.