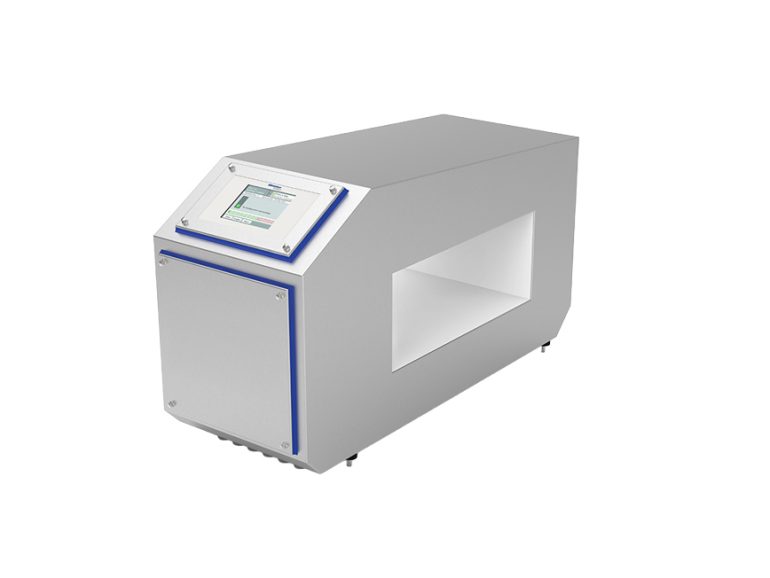

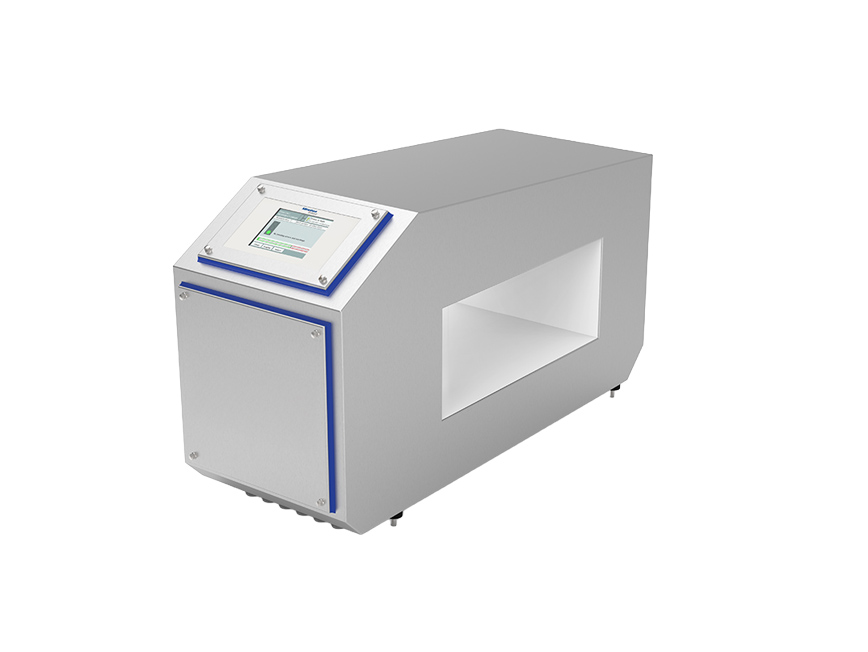

Metal detector

To guarantee the safety and compliance of your products, we integrate industrial metal detector for production line safety directly into our conveyor and bagging lines. This equipment, sourced from renowned manufacturers, ensures accurate detection of metal particles (ferrous, non-ferrous and stainless steel) while adapting to your production rates and the nature of your products.

Thanks to our expertise in integration, the detector is perfectly synchronised with the conveyor system to guarantee optimal control without slowing down production.

Why integrate a metal detector?

- Food safety: eliminates any risk of metal contamination before packaging.

- Equipment protection: prevents damage to downstream machinery.

- Regulatory compliance: meets IFS and BRC standards requirements.

Your performance guarantee

By integrating a industrial metal detector for Production Line Safety into our conveyor solutions, you get accurate control that meets your process requirements while maintaining production speed. Our teams carry out integration, adjustments and commissioning to ensure an operational installation that is adapted to your industrial environment.

Key benefits

- 01. High-quality sensors selected from recognised manufacturers.

- 02. Wide detection range, suitable for different products and packaging.

- 03. Intuitive interface, easy to use and configure.

- 04. Complete, customised integration into your existing lines or new installations.

- 05. IP65 stainless steel construction, hygienic, robust and easy to clean.

- 06. Full compliance with current safety and quality standards.

Ready to discuss your industrial needs?

Our technical team understands the specific challenges of each sector.

Let us help you find the ideal bagging solution for your application.