Safety Sieve

The HALPAQ safety sieve, installed upstream of the bagging machine, removes foreign bodies and controls particle size to prepare powders before packaging. Two technologies are available: vibratory screening and rotary screening, to suit a wide range of powders, from standard products to the most demanding applications.

Description

The safety sieve is designed to meet food safety, chemical and pharmaceutical requirements. It is available in two versions:

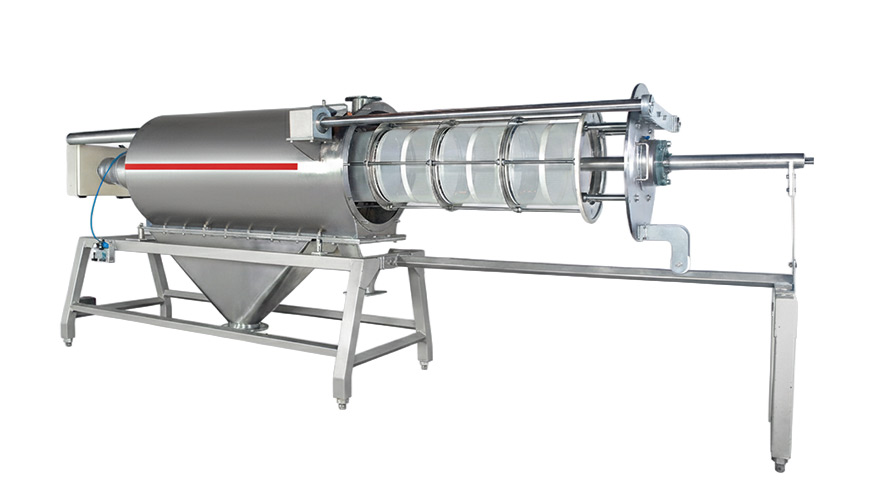

- Vibrating sieve: an oscillating movement ensures that the powder passes through the grid while retaining impurities. Ideal for dry, fine or light powders.

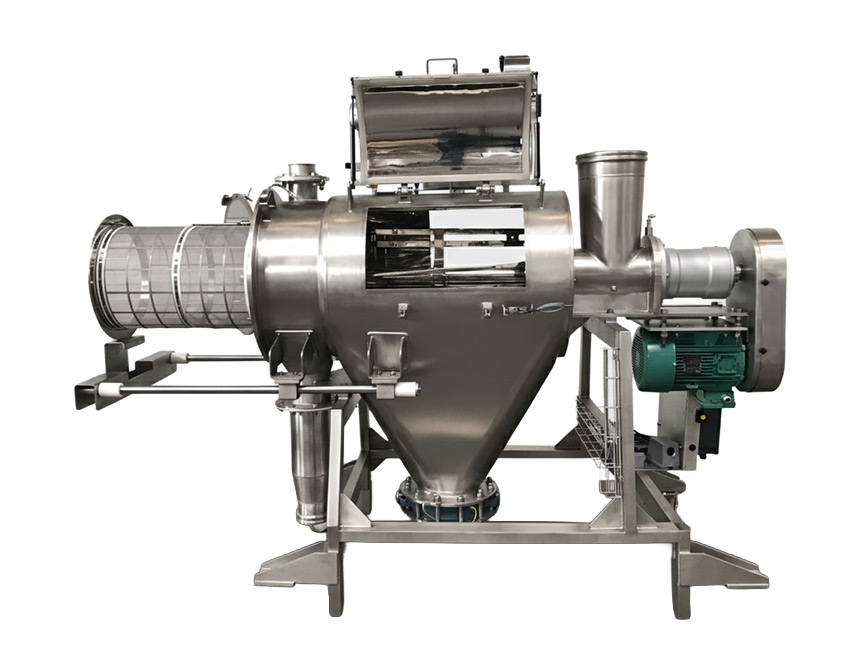

- Rotary (centrifugal) sieve: a helical screw drives the product towards the grid, allowing difficult powders that are slightly damp or sticky to be processed.

This sifter is installed directly upstream of the bag filling line.

Select your finish

Choose from our Washable, Hygienic, and Pharmaceutical configurations.

Hygienic version – 316L stainless steel

316L stainless steel construction for improved corrosion resistance, meeting the requirements of aggressive food and chemical environments.

- Increased resistance to corrosion and chemicals

- Complies with food and pharmaceutical requirements

- Ideal for sensitive powders and critical applications

Basic version – 304L stainless steel

A robust design in 304L stainless steel, suitable for standard industrial environments.

- Robust construction for standard environments

- Suitable for dry, low-abrasive powders

- Economical and versatile solution

Easy-clean version – Mirror finish

Designed with quick-release grilles and mirror finishes, allowing for simplified cleaning and optimal hygiene for sensitive environments (baby food, pharmaceuticals).

- Smooth surfaces with mirror-polished finish

- Quick removal of grids for frequent cleaning

- Compatible with CIP/CPM processes

- Designed for high-hygiene environments (baby food, pharmaceuticals)

Technical specifications

| Features | Vibrating sieve | Rotary (centrifugal) sieve |

| Flow rate | Up to 7 t/h (depending on powder) | Up to 20 t/h (depending on powder) |

| Mesh size | 2 mm safety margin. Possible up to 500 µm. | 2mm safety margin. Possible up to 200µm |

| Type of movement | Linear/oscillating vibration | Centrifugal force with blades |

| Suitable products | Fine powders, dry pulverised substances | Sticky powders, slightly damp |

| Screen dimensions | Ø 500 to 900 mm | Pipe Ø 220 to 410 mm |

| Manufacturing materials | 304L or 316L stainless steel, FDA seals | 304L or 316L stainless steel, FDA seals |

| Cleaning | Manual or NEP/CIP (optional) | Manual or NEP/CIP (optional) |

| Sound level | 75 dB | 80 dB |

| ATEX | optional | optional |

Custom engineering solutions

Our engineering team can customise every aspect of the system to meet your unique requirements: from bespoke parts to complete systems for your specific processes.

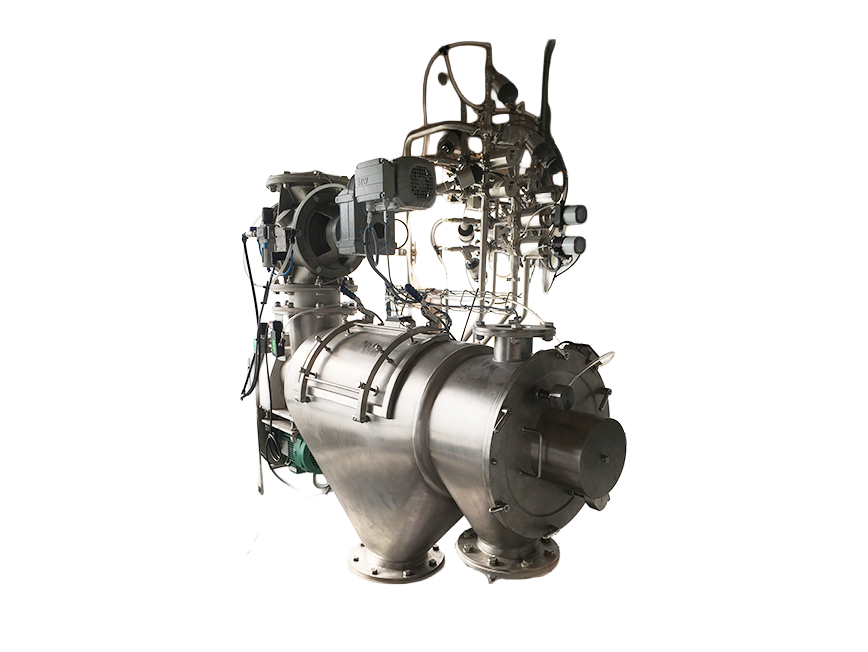

- Clean-in-place (CIP) system

automatic washing without dismantling - ATEX version

for areas with explosive atmospheres (combustible powders). Interchangeable screens - Interchangeable screens

several mesh sizes available depending on the desired particle size. - Mesh breakage detection

alert in case of screen mesh breakage. - Quick disassembly

Crank handle to lift the top cover on vibrating screens and guide rail for removing the screen on rotary screens.

Ready to discuss your industrial needs?

Our technical team understands the specific challenges of each sector.

Let us help you find the ideal bagging solution for your application.