Client application

Pneumatic Conveying and Packaging Line for Food Ingredients and Flavors from Spray Dryer

Do you have a similar project ?

Context & customer needs

As part of its production process optimisation programme, a manufacturer of vegetable-based food ingredients wanted to modernise and automate the packaging line for its finished products from an atomisation tower. The main objective was to ensure continuity of flow between the production of powders (such as mushroom, beetroot, pepper and tomato) and their packaging, while complying with the highest standards of industrial hygiene.

Our client’s objectives were:

- To connect the atomisation tower directly to the conical mixer.

- To ensure hygienic, confined handling without cross-contamination.

- To optimise the ergonomics of the workstation and limit manual handling.

- To control deaeration for compact and stable 25 kg bags.

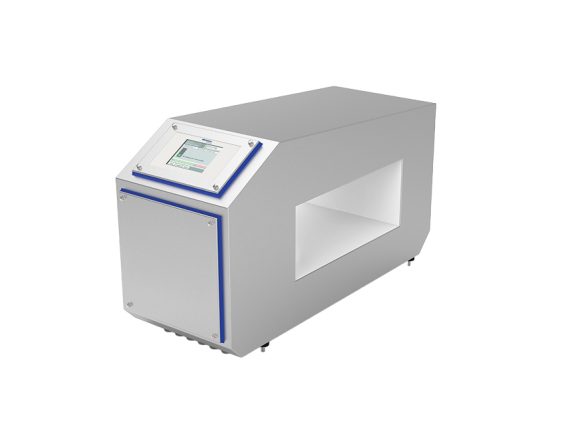

- To integrate a checkweigher and metal detector for quality control.

- Enable rapid, automated cleaning in place of critical equipment.

This project was designed to increase productivity, improve packaging quality and ensure complete traceability of operations in a 24-hour production environment.

Customer product

Food flavourings

Food flavouring powders are ingredients used in the food industry to impart or enhance a specific taste and aroma in finished products.

The solution provided

To meet the customer’s requirements for continuity, hygiene and efficiency, Halpaq designed a comprehensive solution incorporating several specific pieces of equipment

A complete solution

- Gentle, fully enclosed VFlow® pneumatic transfer of powders.

- Hygienic 304L stainless steel equipment with integrated CIP.

- Conical mixer: optimal homogenisation and complete emptying.

- Flexible food-grade screw for gentle transfer to the packaging machine.

- HALPAQ station: bottom-up filling, densification and deaeration of 25 kg bags.

- Rapid CIP/SESSAD, weight and metal control, PalTouch® control connected to MES/ERP.

To meet these requirements, the implemented solution combines a VFlow® vacuum pneumatic transfer system, a conical rotary screw mixer and a flexible screw, thereby ensuring gentle and hygienic powder conveyance to the HALPAQ packaging station. In addition, the entire line, designed in 304L stainless steel and engineered for CIP/SESSAD, enables rapid cleaning in place, while at the same time ensuring efficient deaeration of 25 kg bags through bottom-up filling, a vibrating tray and a suction rod, resulting in total dust containment. Furthermore, in-line quality control is provided by a checkweigher and a metal detector. Finally, automated control via the PalTouch® touch screen, together with Ethernet communication, allows seamless integration with the customer’s MES/ERP system.

Benefits for the customer

- Continuous flow from powder to packaging, without interruption or mixing of batches.

- Confined handling, dust-free, strict compliance with hygiene standards.

- Improved operator ergonomics, less handling and fewer musculoskeletal disorders.

- Compact, stable, deaerated and perfectly sealed 25 kg bags.

- Rapid CIP/SESSAD cleaning, significantly reduced production downtime.

- Enhanced quality control: weight, metals, complete batch traceability.

- Centralised PalTouch® control, MES/ERP integration, secure 24/7 production.

Products handled

This facility processes a wide range of powders and granules with challenging characteristics:

- Fine, hygroscopic powders derived from dehydrated plant ingredients.

- Abrasive or fragile granules requiring gentle and controlled conveying.

- Products with variable density and high dust content.

- Multi-reference mixtures with frequent changes in production.

The equipment used for this project

Do you have a similar project ?

Are you looking to design a hygienic, automated and compact packaging line

for your food, nutraceutical or animal feed powders ?