Powder samplers – SAMP range

The SAMP range of powder samplers enables samples to be taken from powdery or bulk representative materials directly from process lines. It ensures batch traceability, process safety and continuous quality control in demanding environments such as the food industry and chemical industry.

Description

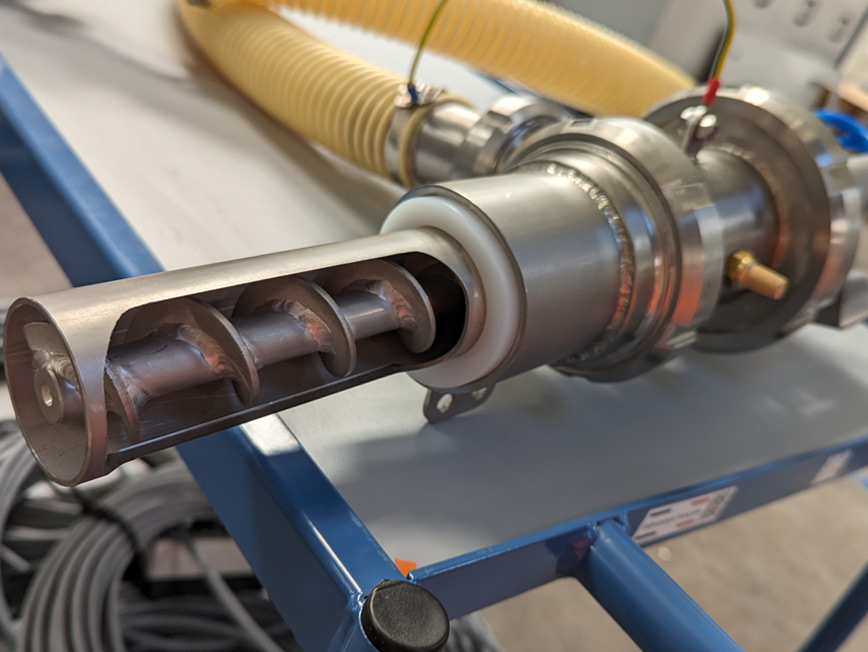

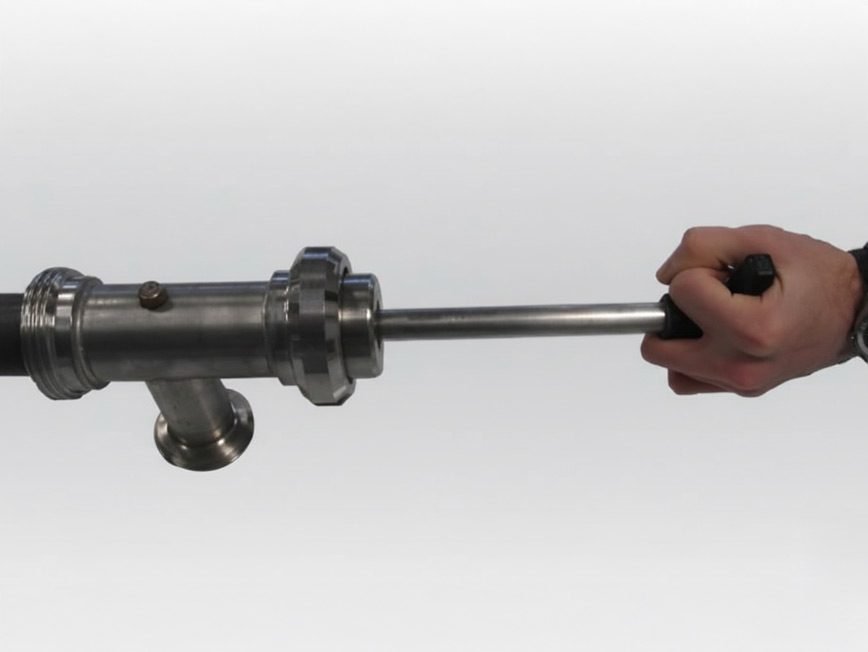

SAMP samplers are designed to collect reliable and reproducible samples of powders, granules or powdered products directly in line. Installed on gravity pipes, they enable quality control, microbiological analysis and complete batch traceability. Two technologies are available:

- Piston technology: ideal for spot sampling, collecting volumes of 10 to 100 ml per cycle, in manual or automatic pneumatic versions.

- Screw technology: designed for continuous or discontinuous sampling, from 50 to 500 g/min, in manual or motorised versions.

Each model is constructed from mirror-polished 304L or 316L stainless steel with FDA/EHEDG-compliant seals and hygienic connections (SMS or clamp). The design limits retention areas and allows for easy cleaning, either manually or in situ (CIP/NEP). The ATEX zones 20/22 versions ensure safe use in dust-hazardous environments.

Key benefits

- 01. Reliable, reproducible and representative sampling.

- 02. Piston or screw technologies adapted to each process.

- 03. Hygienic design with no retention areas.

- 04. Manual or automated cleaning (CIP/NEP).

- 05. Robust construction in mirror-polished 304L/316L stainless steel.

- 06. FDA and EHEDG compliant seals.

- 07. ATEX compatible zones 20/22.

- 08. Easy integration into gravity pipes.

- 09. Suitable for the food, chemical and pharmaceutical industries.

Ready to discuss your industrial needs?

Our technical team understands the specific challenges of each sector.

Let us help you find the ideal bagging solution for your application.