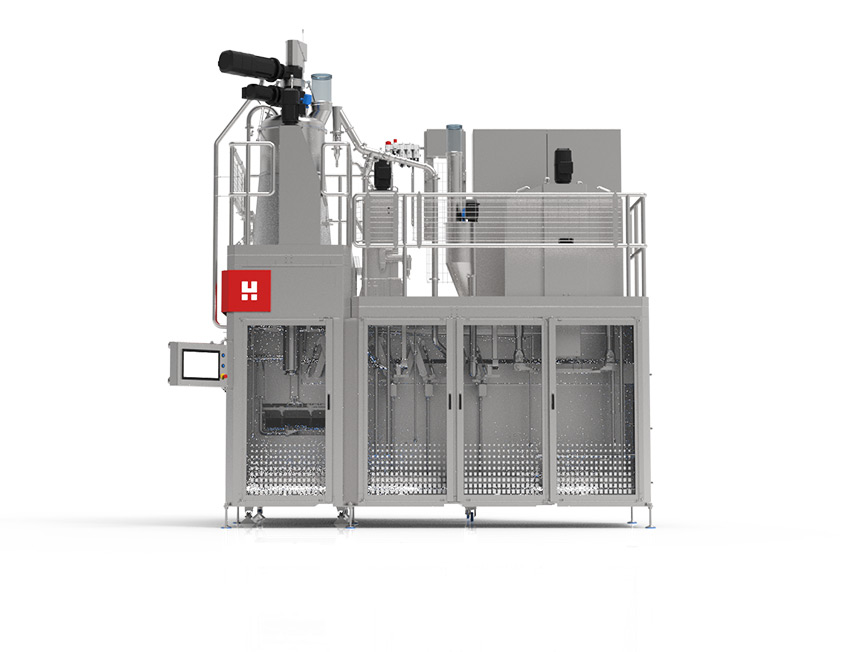

BM 1040

Automatic bagging machine

for open-mouth bags

The BM1040 embodies the optimal compromise between compactness, high speed and weighing accuracy. Designed for demanding production lines, it combines productivity of up to 400 bags/hour with exceptional accuracy of ±20 g, all in a small footprint. Its hygienic design ensures a safe and easy-to-clean process.

Description

The BM1040 is a high-speed automatic bagging machine, specially designed for packaging demanding powdered products. It combines performance, cleanliness and product integrity to meet the most stringent standards in the food, chemical and pharmaceutical industries.

Its patented filling technology is at the heart of its performance. This technology significantly reduces dust emissions and product aeration, making it ideal for sensitive powders (additives, vitamins, active ingredients) and ensuring a clean and controlled production environment.

The packaging process is organised around four separate workstations:

- main filling

- deaeration

- finishing filling

- sealing

This process ensures a fast cycle time, exceptional weighing accuracy and optimal protection of your product’s integrity.

Designed with the operator in mind, the BM1040 combines safety, hygiene and ease of use. Its dust-free operation, low maintenance and surfaces optimised for quick cleaning make it the benchmark solution for the hygienic packaging of your powders.

Key features

Design compact

Compact design for easy integration into existing production lines.

Automatic format change

Quick and automatic adjustment of settings for effortless transition between different bag and product formats, maximising your production time.

Unrivalled versatility

Capable of handling a wide range of bag formats (with or without gussets) and product types (powders, granules).

Continuous bag guidance and control

Holding and monitoring system ensuring perfect positioning and stable, precise operation from filling to closure.

Custom designs for hygiene

Unique on the market, available in three hygiene levels (Cleanable, Hygienic, Cleanroom) to meet the most stringent requirements of your industry (FDA, GMP, ATEX, EHEDG).

Technical specifications

| Filling weight range | 5 to 30 kg |

| Maximum speed | Up to 400 bags per hour |

| Weighing accuracy | ± 20 g |

| Compressed air consumption | 150 Nl/bag at 4 bar |

| Dimensions (L x W x H) | 3,000 x 2,500 x 4,500 mm |

| Machine weight | 2,500 kg |

Select your finish

Choose from our Clean, Hygienic and Pharmaceutical configurations.

CBM 1040 – “Clean”

Designed for less demanding products and environments. Designed to be cleaned manually.

- Tubular, open frame

- RAL 7035 painted steel structure

- Parts in contact with the product in 316L stainless steel

- Centralized aspiration

- Design in accordance with EHEDG standards

Ideal when hygiene is not critical.

Objective: Accessible surfaces, no product retention and no visible cables.

HBM 1040 – “Hygienic”

Designed for regular, intensive automatic or manual cleaning.

- Closed frame with product retention trays

- 304 stainless steel structure

- Parts in contact with the product made of 316L stainless steel

- Centralized aspiration

- Design compliant with EHEDG standards

- CIP network optional

- Inerting optional

Made of 304 stainless steel, designed for frequent cleaning.

Objective: Smooth surfaces without retention, mechanisms that can be dismantled without tools, possibility of drying in place.

PBM 1040 – “Pharmaceutical”

Designed for intensive and regular cleaning and sterilisation.

- Closed frame with product retention trays

- 316L stainless steel structure

- Parts in contact with the product made of 316L stainless steel

- Centralized aspiration

- Design compliant with EHEDG standards

- CIP network optional

- Inerting optional

- Optional sterilisation

High-end finish for the pharmaceutical industry.

Objective: Polished stainless steel (Ra 0.4) compliant with GMP requirements. Fully accessible surfaces, with no retention areas or visible cables. Mechanisms can be dismantled without tools for cleaning and drying in place (CIP/SIP).

Auxiliary equipment

Our engineering team can customise every aspect of the system to meet your unique requirements: from bespoke parts to complete systems for your specific processes.

- Automatic bag sealer

- Semi-automatic bag closing line

- Clean-in-Place (CIP) station

- Drying-in-Place (DIP) station

- Vacuum Inerting Skid

- Reject conveyor

- Labelling machine - Printer

Deaeration probe to remove air from the product.

Vibrating bottom for compacting and stabilising the product in the bag.

Air evacuation system (trimming) for stable palletising and evenly shaped bags.

Filling system specific to the characteristics of your product.

Fields of application

Our bagging solutions meet the most stringent requirements of the chemical, food & feed and pharmaceutical industries, guaranteeing hygiene, safety and productivity. Halpaq adapts each packaging line to your specific requirements, whatever your products and volumes.

Is your sector of activity not listed?

Materials handled

Powders

& Fine Powders

- Milk powder

- Protein powder

- Vitamin powder

- Food additives and for animal feed

- Aromatic herbs and ground spices

Pellets

and Medium Granule Size Products

- Sugars (crystal, semolina)

- Frozen fruit and vegetables (small pieces)

- Chemical granules

- Food supplements (nutraceuticals) in granules

Special materials

- Active Pharmaceutical Ingredients (APIs)

- Nutraceuticals (food supplements) in powder form>

- Peptides and collagen in powder form>

Ready to discuss your industrial needs?

Our technical team understands the specific challenges of each sector.

Let us help you find the ideal bagging solution for your application.