Client application

New Hygienic High-Precision Bagging Machine for Milk Powder with High Throughput

Do you have a similar project ?

Context & customer needs

The customer wanted to replace an ageing bagging machine that was no longer able to meet the speed and hygiene requirements for packaging lactose, milk powder and whey. The old machine did not guarantee the required dosing accuracy or satisfactory dust containment. The objective was to have a high-speed automated line capable of reaching 300 bags/hour while maintaining a strictly hygienic environment. The solution also had to adapt to the constraints of the factory and ensure reliable hermetic packaging. Finally, the customer wanted to integrate online quality control devices to secure each stage of the process.

Our client’s objectives were

- Achieve a stable output of 300 bags per hour.

- Improve dosing accuracy.

- Enhance hygiene and containment.

- Adapt to the available space.

- Ensure airtight sealing.

- Integrate online quality control.

- Reduce product loss.

- Meet agri-food standards.

Customer product

Sensitive milk powders

Dehydrated powder, such as lactose, milk powder or whey, is obtained by removing water to ensure stability, preservation and ease of transport. It is essential in the food industry for the formulation of dairy, nutritional and industrial products thanks to its long shelf life and high precision of use.

The proposed solution

The solution consists of a high-speed CBM 1030 automated bagging line, ensuring accurate, hygienic and fully contained bottom-up filling. It incorporates high-precision dosing, deaeration, hermetic sealing, in-line quality control and centralised suction to guarantee performance and food industry compliance.

The solution implemented includes:

- CBM 1030 automatic bagging station

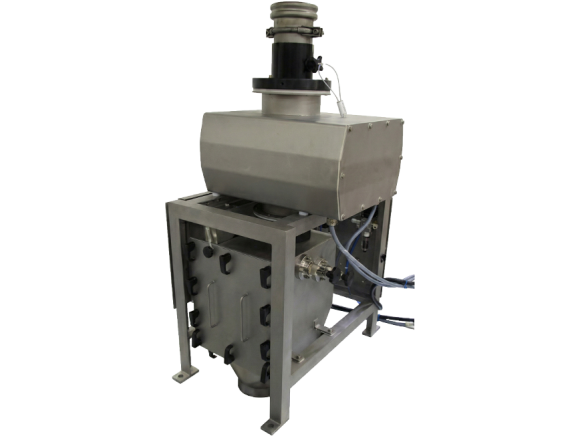

- Vertical screw feeder with 400 L hopper

- Deaeration station with porous lances

- FTS hermetic sealing system

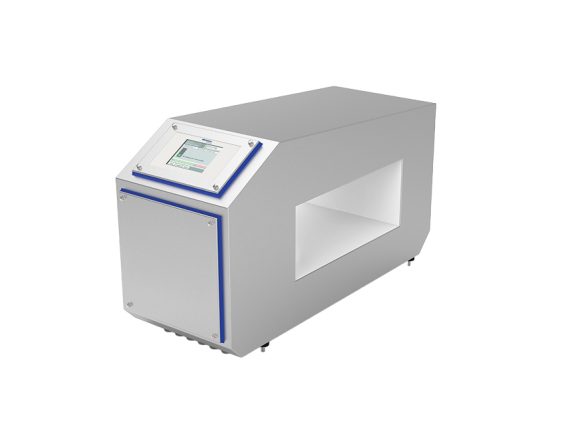

- Dynamic checkweigher with automatic ejection

- 650 m³/h centralised suction system

- 316L in-line sampler

- 316L removable feed screw

- Height-adjustable conveyors

- Integrated magnetic detection

Benefits for the customer

- High output of up to 300 bags/hour.

- Enhanced hygiene EHEDG + ATEX.

- Highly accurate dosing ±30 g.

- Reduced dust.

- Reliable hermetic seal.

- Automated quality controls.

- Flexible multi-format line.

- Quick and easy cleaning.

The equipment used for this project

Equipment

Do you have a similar project ?

Are you looking to design a hygienic, automated and compact packaging line

for your food, nutraceutical or animal feed powders ?