Client application

Installation of a Hygienic Packaging Line for Fatty Food Powders

Do you have a similar project ?

Context & customer needs

In a context of strong growth, the customer wanted to create a new workshop capable of packaging particularly fatty meat and stock powders. The objective was to install a hygienic, high-performance line that could operate continuously for a week without intermediate cleaning. The process had to guarantee a high level of automation to limit human intervention and reduce operating costs. The customer was also looking for a solution that would prevent clogging of high-fat powders and ensure accurate and safe packaging.

Our client’s objectives were

- To modernise the production facility.

- To package complex fatty powders.

- To operate for a week without cleaning.

- Achieve 2,000 to 3,000 tonnes/year.

- Automate as many steps as possible.

- Reduce operator presence.

- Prevent clogging of fatty powders.

- Ensure accurate and stable packaging.

- Enhance product safety.

Customer product

Fat powder

Edible fat powder is a dehydrated ingredient rich in lipids, used to add energy, texture and creaminess to preparations. It improves the stability, preservation and taste of food products such as broths, sauces, nutritional mixes and animal feed.

The proposed solution

HALPAQ has designed a complete, automated packaging line that integrates screening, product safety, transfer, weight filling, final detection and packaging. The entire system is made of 316L stainless steel and designed to process fatty powders continuously, with CIP cleaning and advanced automation to reduce operator intervention.

The solution implemented includes:

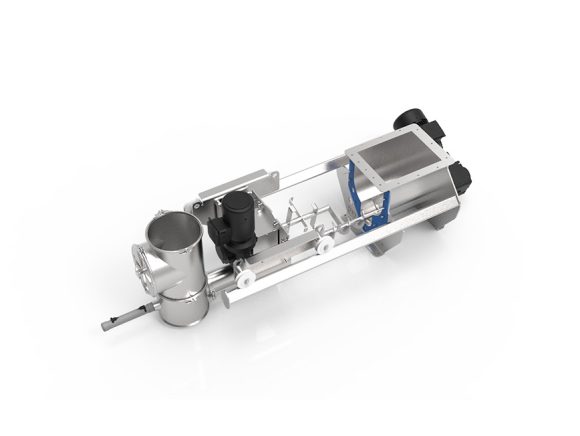

- RS300 centrifugal sieve

- Screw sampler

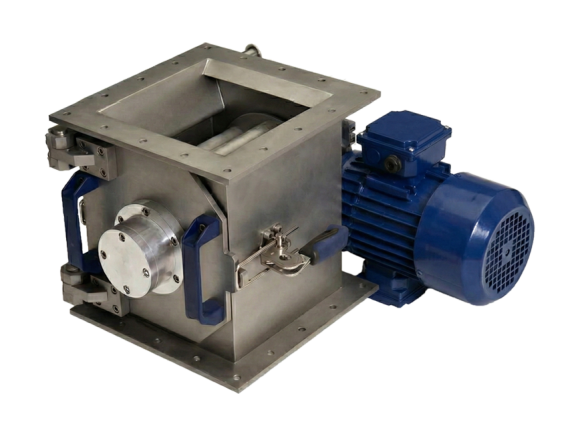

- Magnetic grids

- Gravity ejector metal detector

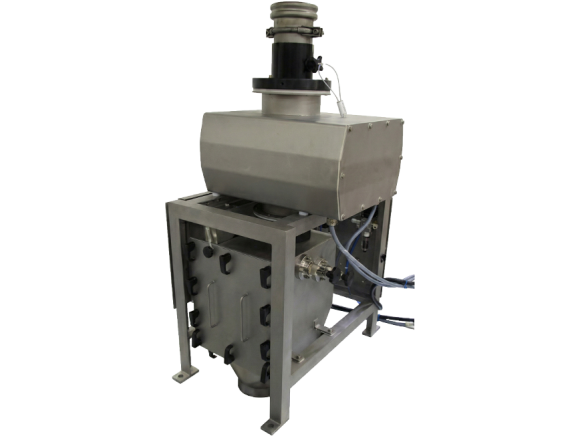

- Vibrating chute

- HALPAQ HBM1030 automatic bagging machine

- Motorised output conveyor (17 bags)

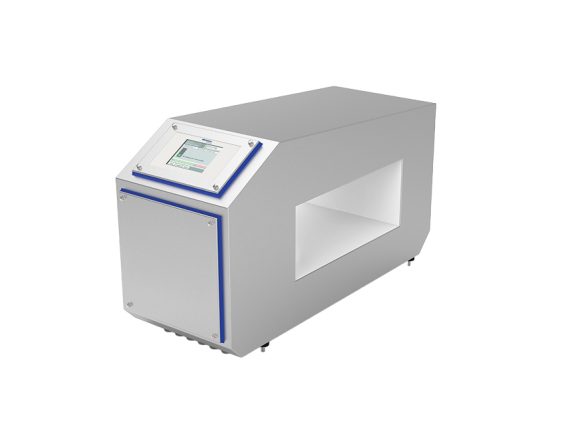

- Final metal detection tunnel

- Semi-automatic carton former + automated closure

The powder produced by drying is first sieved in an RS300 centrifugal sieve to remove foreign bodies and break up lumps. A screw sampler automatically takes quality samples, then a double metal safety system (magnetic grid + metal detector) ensures product compliance. The powder is then transferred by a vibrating chute to the HALPAQ HBM1030 bagging machine, the heart of the line, which automatically weighs, deaerates and seals the bags. The filled bags are conveyed, checked one last time by a metal detection tunnel, then placed in cartons via a semi-automatic forming machine and an automated sealing machine. The whole line is completely hygienic, automated and suitable for fatty powders.

Benefits for the customer

- Hygienic line suitable for fatty powders.

- Continuous production without intermediate cleaning.

- Reduced operator intervention.

- Product quality assured at every stage.

- Precise and stable packaging.

- High and consistent productivity.

- Reduced risk of clogging.

- Easy maintenance thanks to CIP.

Processed products

Processed products are meat and poultry stock powders, characterised by a high fat content. These fatty powders are sensitive, sticky and can present clogging risks, requiring a specific, hygienic processing line that is perfectly suited to their behaviour.

The equipment used for this project

Equipment

Do you have a similar project ?

Are you looking to design a hygienic, automated and compact packaging line

for your food, nutraceutical or animal feed powders ?