Client application

Replacement of semi-manual bagging with a high-speed automatic line for nutraceutical powders

Do you have a similar project ?

Context & customer needs

A French manufacturer of powdered food supplements wanted to modernise its packaging line by implementing an automated bagging line for nutraceutical powders. Initially designed for low-speed manual bagging, the project quickly evolved into an automatic, hygienic solution to keep pace with increasing demand and meet stricter regulatory requirements.

Our customer’s objectives were:

- To improve the hygiene conditions and cleanability of its machine.

- To increase productivity without increasing the number of operators

- To guarantee consistent accuracy in order to control material costs.

Technical challenges

The production environment presented several major technical constraints:

- Variety of powders handled: very fine silica, dense lithothamnion, lactose and carbonates — all of which had to be processed using the same equipment.

- High risk of clogging in the equipment due to the characteristics of the products.

- Integration into an existing line comprising three mixers, a pneumatic transfer system, a liquid injection system and a gravity discharge system, requiring adaptation to the available space.

- Maintaining a target rate of 150 bags/hour, while controlling air consumption to reduce energy costs.

Customer product

Nutraceutical powders

These specialised ingredients include very fine silica, lithothamnion, lactose and carbonates. They are used in food processing and technical formulations to improve texture, provide minerals, facilitate dosing and ensure stability and versatility. They also contribute to the final quality of the products.

The solution provided

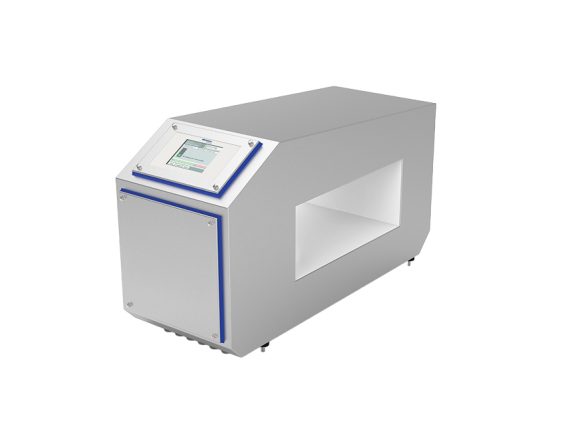

To meet these challenges, Halpaq proposed and installed an automated bagging line for nutraceutical powders based on a PBM1030 automatic open-mouth bagging machine, designed to deliver precise dosing, high hygiene standards and high production rates.

The solution implemented includes:

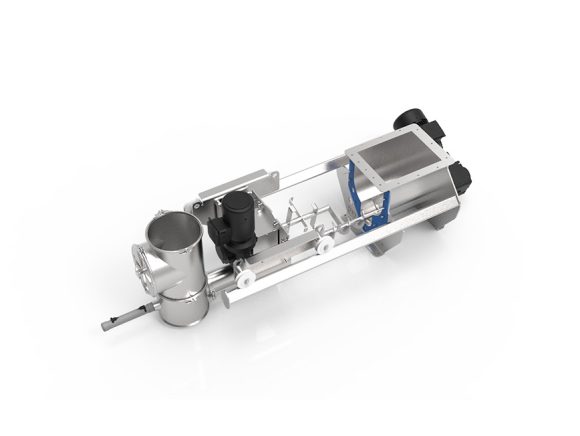

- Automated feeding of the bagging machine by a transfer screw, with integrated vibrator to ensure flow.

- Sealed connection between the screw and the bagging machine with magnetic filter and reserve for vibrating sieve.

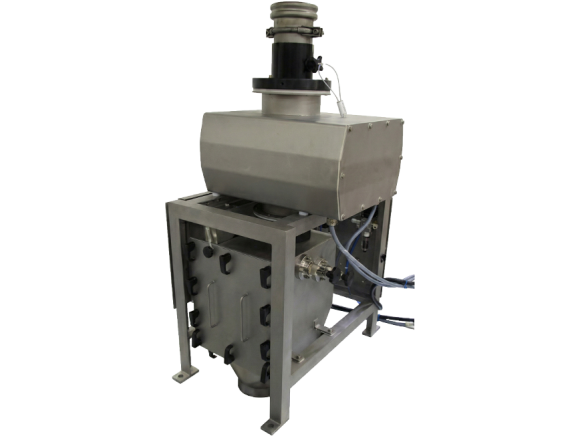

- 3-stage filling system: controlled dosing, product deaeration and sealing.

- Centralised suction at each critical point to maintain a clean working environment.

- Palletising: connection of the bagging machine to the existing palletising system.

Products handled

This facility processes a wide range of powders and granules with challenging characteristics:

- Lightweight, hygroscopic powders: silica, vitamins, protein powders

- Mineral products: calcium carbonate, clays, lithothamnion

- Moisture-sensitive food additives and nutraceuticals

- High value-added formulated blends for food supplements

Results obtained

| Criteria | Preliminary draft | After installation |

|---|---|---|

| Bagging rate | ~60 bags/hour | Up to 150 bags/hour |

| Operator intervention | High | Almost zero. For refilling empty bags. |

| Dosing accuracy | ±100 g | ±20 g |

| Air consumption | High | ≈ 45,000 NL/h at 4 bar |

| Cleaning | Long and manual | Optional automation (CIP/NEP) |

Benefits for the customer

- Tripled throughput with maintained precision.

- Fully automated process, reducing human risk.

- Enhanced hygiene for sensitive nutraceutical powders.

- Reduced dust emissions and improved operator safety.

A unique synergy HALPAQ × Palamatic

To meet these requirements, Palamatic Process designed and delivered a complete solution combining HALPAQ technologies and process integration expertise:

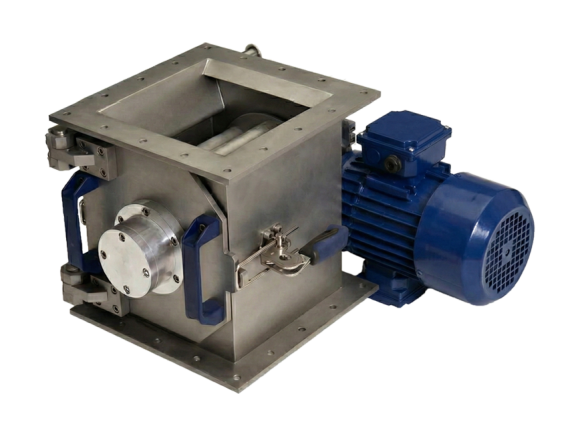

- Rotary safety screen placed upstream of the line to ensure that there are no contaminants or foreign bodies before bagging.

- PBM1030 automatic hygienic bagging machine, the heart of the line, offering precise dosing, automated cleaning and minimal space requirements.

- Fully automated downstream cartoning line for conveying, closing and shipping bags.

- At the same time, a second big bag filling line has been integrated, optimised for speed, ease of cleaning and logistical fluidity.

The equipment used for this project

Equipment

Do you have a similar project ?

Are you looking to design a hygienic, automated and compact packaging line

for your food, nutraceutical or animal feed powders ?