Client application

Hygienic Bagging Line with Rotary Sifter and Automated Case Packing

Do you have a similar project ?

Context & customer needs

The customer, a manufacturer of meat powders for animal nutrition and the food industry, wanted to modernise its packaging process by installing two ultra-hygienic lines adapted to strict regulatory requirements. The project was based on a hygienic bagging line with rotary sifter, designed to increase production speed while optimising the layout within a limited footprint. It included a 25 kg bagging line with automated cartoning and a big bag line with complete logistics management. All process stages were designed to be cleanable manually and/or automatically via CIP/NEP, ensuring maximum hygiene and minimal operator intervention.

Our client’s objectives were

- To modernise the packaging process.

- To comply with strict hygiene standards.

- To increase production speed.

- To optimise floor space utilisation.

- Reduce operator intervention.

- Integrate automated CIP/NEP.

- Package in bags and big bags.

- Ensure reliable and hygienic closure.

The customer wanted to set up two ultra-hygienic packaging lines capable of increasing throughput while fitting into a limited space. The aim was also to reduce operator intervention through CIP/CPE cleaning and complete automation of flows.

Customer product

Meat powder

The lines handle meat powders intended for the food industry and animal nutrition, sensitive products requiring rigorous hygiene. These powders generate dust and agglomerates, hence the need for secure sieving, precise dosing and perfectly sealed packaging.

Halpaq & Palamatic Process Solution

The solution is based on a hygienic bagging line with rotary sifter, combining a rotary sieve, an HBM1030 hygienic bagging machine and a fully automated cartoning line. It is complemented by a second big bag line, fully cleanable via CIP/NEP. The complete system forms a compact, ultra-hygienic and highly productive installation.

The solution implemented includes:

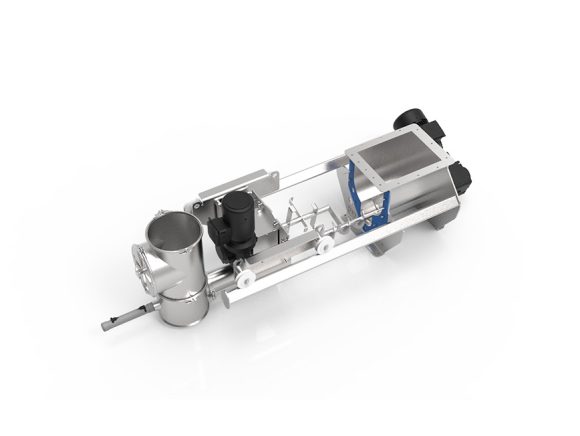

- Rotary safety sieve

- Buffer hopper weighed on load cells

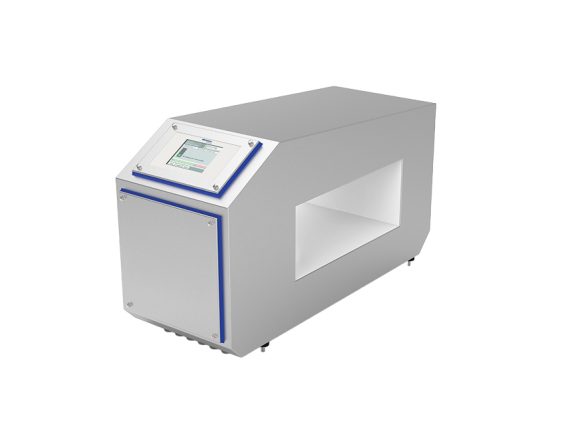

- HBM1030 hygienic bagging machine

- ±20 g screw dosing system

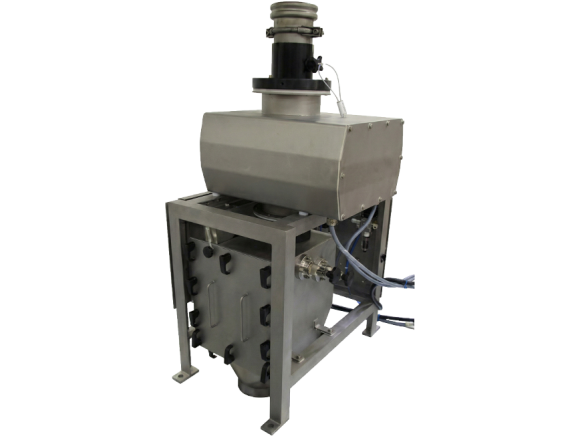

- CIP nozzles and Dry In Place system

- Bag closure: welding or sewing

- Conveyor to robotic packing station

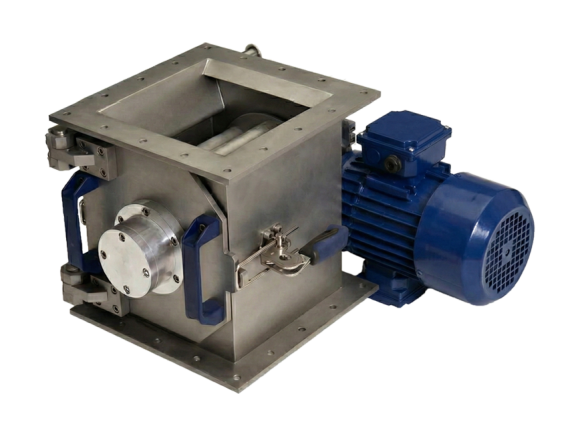

- EasyClean® stainless steel big bag line

- Pneumatic collar + double-walled sleeve

- Gravity hopper + guillotine valve

- Motorised pallet conveyor

- Automated storage area evacuation

- Centralised control via Pal’Touch® screen

Overall operation of the line

The product is sieved and then measured via a weighing hopper before being automatically bagged by the HBM1030. The bags are then closed, conveyed and placed in cartons via a robotic station. At the same time, the big bag line automatically fills, flanges and evacuates the containers in a continuous hygienic flow.

Products handled

The lines handle meat powders intended for the food industry and animal nutrition, sensitive products requiring rigorous hygiene. These powders generate dust and agglomerates, hence the need for secure sieving, precise dosing and perfectly sealed packaging.

Customer benefits

- Maximum hygiene via CIP/SIP.

- Significantly reduced operator intervention.

- High and stable output.

- Optimised compact installation.

- Enhanced operator safety.

- Process with no retention areas.

- Automated boxing.

- Streamlined big bag logistics.

A unique synergy HALPAQ × Palamatic

This project illustrates the perfect complementarity between Halpaq’s expertise in hygienic bagging solutions and Palamatic Process’s global engineering.

The result:

A facility that meets the most demanding standards in the food and animal nutrition industries, is automatically cleanable, highly productive and perfectly integrated into the customer’s industrial environment.

The equipment used for this project

Equipment

Do you have a similar project ?

Are you looking to design a hygienic, automated and compact packaging line

for your food, nutraceutical or animal feed powders ?