Client application

Hygienic Automatic Bagging Machine with CIP for Dried Yeast

Do you have a similar project ?

Context & customer needs

A major producer of dehydrated yeast (powder & flakes) wanted to improve the efficiency and hygiene of its packaging process. Until then, cleaning required the complete dismantling of the line by two operators, taking four hours of work and causing a production stoppage of 2.5 days, resulting in a significant loss of earnings.

Product specificity: highly sensitive to moisture and bacterial contamination, requiring pharmaceutical-grade standards. Packaging had to be carried out directly after drying, without intermediate storage, to avoid any product retention.

Customer’s technical expectations

- Quick format changeover (10, 15 and 25 kg) without mechanical dismantling.

- Bag-in-box integration to protect the product and limit contamination. Thanks to Halpaq’s flexibility, the same station can be used to bag or bag-in-box without any human intervention.

- Preservation of the fragile texture of the flakes: avoiding free falls, heating and crushing.

- Automated cleaning in place (CIP) with restart in ≤ 4 hours after a complete cycle (pre-rinsing, alkaline/acid washing, filtered & recycled hot air drying).

- High containment thanks to sealing sleeves, closed and dust-free areas.

- Centralised control with integrated traceability: recipes, CIP cycles, archiving, alarms, quality monitoring.

Technical challenges

The project had to reconcile industrial performance, food safety and operational flexibility while respecting the specific characteristics of a sensitive product such as dehydrated yeast.

- Drastic reduction in cleaning time: from 2.5 days with several operators to 4 hours with a single operator.

- Maintenance of a high production rate with a dosing accuracy of ±20 g.

- Preservation of the particle size and fragile structure of the yeast flakes.

- Strict hygiene: no residual moisture, no cross-contamination or external contamination.

- Operational versatility: conventional bagging or bag-in-box on the same workstation.

Customer product

Dehydrated yeast

Dehydrated yeast is yeast that has had its moisture content significantly reduced to ensure stability, preservation, and microbiological performance. It is widely used in the food industry for fermentation, flavoring, and improving the nutritional properties of products.

Halpaq solution proposed

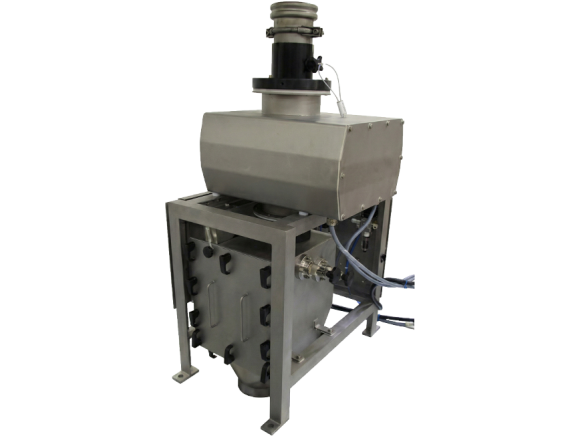

Palamatic Process has designed a 100% hygienic automated bagging line, connected directly to the dryer outlet. This configuration guarantees immediate packaging, preserving the quality of the yeast and its low hygroscopicity.

The solution includes:

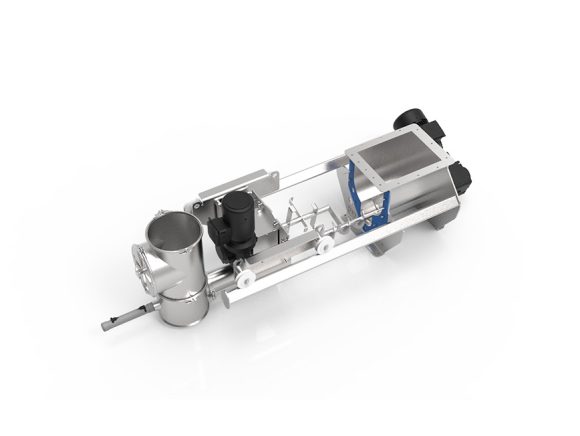

- Bottom-up filling limiting dust and preventing free falls. The bag descends as the product level rises, ensuring better densification and total preservation of product integrity.

- Progressive deaeration via micro-perforated lances + vacuum generator to achieve uniform density and ensure a stable and regular pallet.

- Bag-in-box elevator conveyor ensuring controlled placement without impact or deformation.

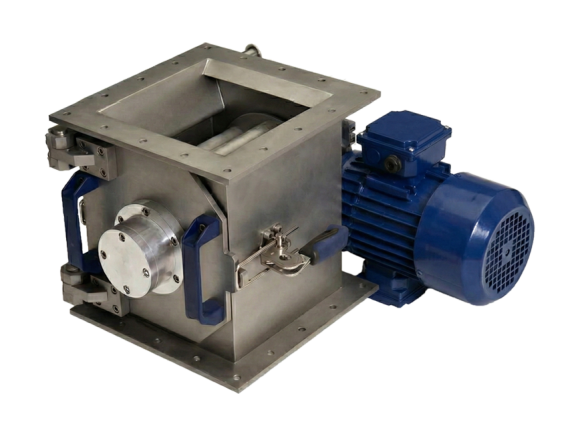

- Automated CIP system: 15 nozzles positioned on critical areas, coupled with a 50°C hot air blower with on-board filtration.

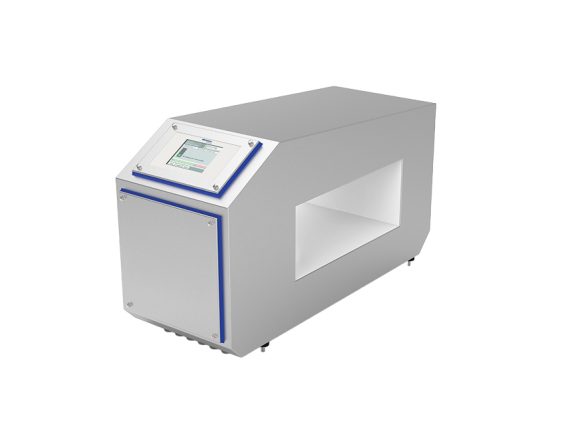

- Ergonomic control via HMI, Industry 4.0 compatible (OPC/UA), with integrated archiving and quality monitoring.

Line operation

- Bottom-up feeding and filling for 10, 15 or 25 kg formats.

- Deaeration via micro-perforated lances with controlled compaction.

- Bag placement in direct bagging mode or bag-in-box mode thanks to a height-adjustable conveyor.

- Closing and identification via industrial labeller.

- Integrated quality control: dynamic checkweigher, metal detector and automatic ejection system.

- Automated cleaning in place (CIP): pre-rinsing, washing and drying with filtered hot air.

Results & performance

| Criterion | Preliminary draft | After installation |

|---|---|---|

| Cleaning time | 2.5 days | ≤ 4 h |

| Labour force | 2 operators | Automated |

| Dosing accuracy | ±50 g | ±20 g |

| Dust containment | Limited | Optimised |

| Product integrity | Crush hazard | Soft filling |

| Secondary packaging | Manual | Automated |

Benefits for the customer

- Significant reduction in cleaning time: saving of 2.5 days → 4 hours.

- Labour savings thanks to automation.

- Maintenance of product integrity (no settling of flakes).

- Improved hygiene with automated CIP/CIP and hot air drying.

- Versatility (traditional bagging or bag-in-box).

- Enhanced traceability and quality with metal detection, dynamic weighing and automatic rejection.

Products handled

- Dehydrated powdered yeast

- Fragile yeast flakes

- Products sensitive to moisture and contamination, requiring hygienic and immediate packaging

A unique synergy HALPAQ × Palamatic

This project illustrates the perfect complementarity between Halpaq‘s expertise in hygienic bagging solutions and Palamatic Process‘s global engineering.

The result: a facility that meets the most demanding standards in the food and animal nutrition industries, is automatically cleanable, highly productive and perfectly integrated into the customer’s industrial environment.

| Parameter | Value |

|---|---|

| Bag formats processed | 10, 15 and 25 kg |

| Dosing accuracy | ±20 g |

| Complete cleaning time | ≤ 4 h |

| NEP/CIP buses | 15 buses fixes |

| Cycle NEP/CIP | pre-rinse, alkaline, acid, hot air drying at 50°C |

| Density of processed products | fine powder & fragile flakes |

| Detection & quality control | Metal detector, checkweigher, automatic rejection |

| Hygienic protection | IP69K critical areas |

| Integration | OPC/UA – Industry 4.0 compatible |

The equipment used for this project

Equipment

Do you have a similar project ?

Are you looking to design a hygienic, automated and compact packaging line

for your food, nutraceutical or animal feed powders ?