Client application

Automatic bagging machine for powdered milk

Do you have a similar project ?

Context & customer constraints

A dairy manufacturer needed to modernise its packaging line. The old bagging machine no longer guaranteed the expected productivity or the required hygiene standards. The main constraints identified were:

- Insufficient speed, below production targets.

- Poor dust control, leading to health risks and material losses.

- Limited dosing accuracy, problematic for sensitive products such as lactose, milk powder and whey.

- Inability to integrate online quality controls.

Customer’s objective: to install a new automated line capable of filling up to 300 bags/hour while ensuring impeccable hygiene and optimal product safety.

Technical challenges

The project had to address several major challenges to ensure performance, hygiene and safety:

- Maintain high speeds with a constant flow rate.

- Ensure dosing accuracy of ±10 g on 25 kg bags.

- Integrate a CIP/NEP system for automatic cleaning.

- Drastically reduce dust emissions with centralised extraction.

- Ensure compliance with EHEDG standards and the ATEX dust zone directive.

Customer product

Powdered milk

Halpaq solution proposed

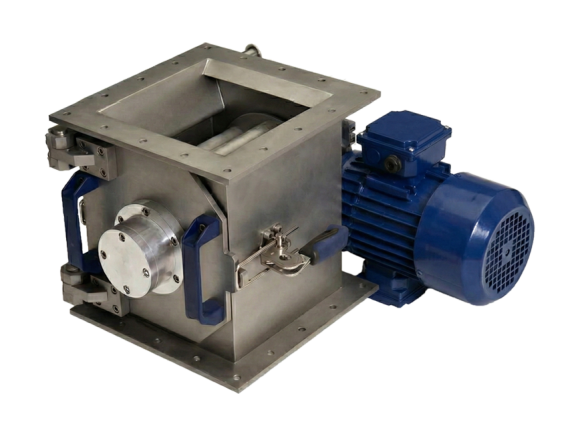

The solution selected is based on a CBM 1030 automatic bagging machine integrated into a complete control line and process security system:

The solution implemented includes:

- CBM 1030 station: up to 400 bags/hour, paper/PE/PP bags, with or without lining.

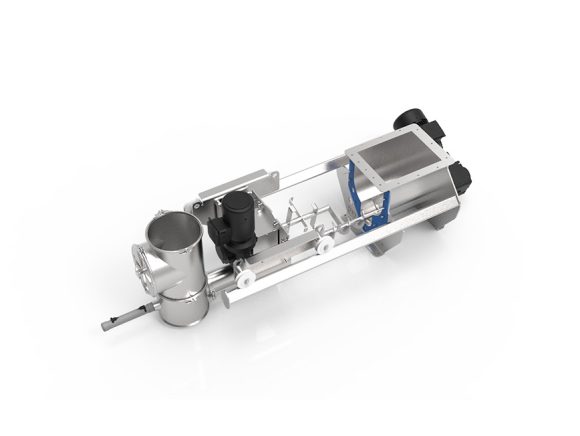

- Vertical screw feeder with 400 L hopper, integrated agitator and ±10 g accuracy.

- Bottom-up filling limiting dust and improving bag compactness.

- Fine dosing station for additional precision.

- Deaeration station with porous lances, ideal for densities of 400 to 770 kg/m³.

- Parallel heat seals with pre-cleaning of the sealing area.

- FTS marketing closure (Fold, Tape, Seal) for hermetic and hygienic packaging.

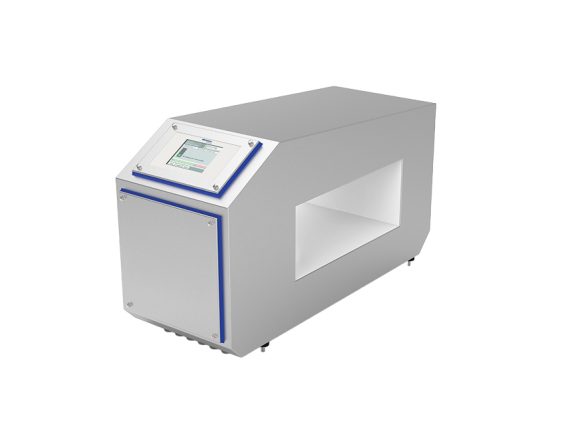

- Checkweigher with automatic rejection of bags outside tolerance (±40 g).

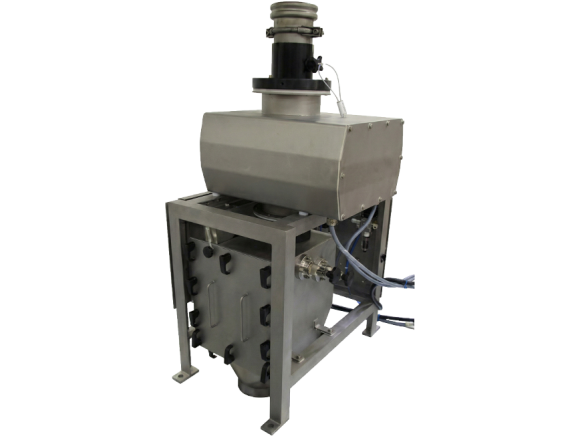

- Centralised suction (650 m³/h at 20 m/s) ensuring a clean working environment.

- Sampler and magnetic detection integrated for complete traceability.

Line operation

- Automatic bag feeding (400-bag magazine).

- Bottom-up opening and filling with gradual bag lifting.

- Controlled deaeration via porous lances.

- Hermetic sealing via FTS technology.

- Dynamic weight control with automatic rejection.

- Continuous dust extraction for a clean environment.

Results obtained

| Criterion | Before (old line) | After (Halpaq solution) |

|---|---|---|

| Cadence | 150–180 bags/hour | 300–400 bags/hour |

| Dosing accuracy | ±60 g | ±10 g |

| Hygiene & dust | Insufficient containment | Centralised vacuum system + NEP |

| Quality control | Manual and random | Dynamic, automatic rejection |

| Regulatory compliance | Partial | EHEDG + ATEX dust zone |

Benefits for the customer

- Doubling of production capacity.

- Increased dosing reliability, reducing material losses.

- Guaranteed health and safety thanks to dust containment and cleaning in place.

- Full regulatory compliance (EHEDG, ATEX).

- Reduced labour costs through automated controls

- Flexibility across multiple bag formats (400–950 mm length, 350–660 mm width).

Products handled

- Lactose

- Milk powder

- Whey

- Products sensitive to humidity, requiring hermetic packaging and uniform densification

A unique synergy between

HALPAQ and Palamatic

To meet these requirements, Palamatic Process designed and delivered a comprehensive solution combining HALPAQ technologies and process integration expertise:

| Parameter | Value |

|---|---|

| Cadence | 300–400 bags/hour |

| Bag format | 400–9500 mm x 350–660 mm |

| Dosing accuracy | ±10 g (25 kg bag) |

| Density of treated powders | 400–770 g/L |

| Centralised vacuum system | 650 m³/h at 20 m/s – Ø100 mm |

| Tolerance checkweigher | ±30 g |

| Cleaning | Integrated CIP/NEP |

The equipment used for this project

Equipment

Do you have a similar project ?

Are you looking to design a hygienic, automated and compact packaging line

for your food, nutraceutical or animal feed powders ?