Client application

High-Speed Automated Bagging Line HBM 1040 for Milk Powder

Do you have a similar project ?

Context & customer needs

The customer needed to replace an ageing bagging machine that was unable to meet the required production rates or comply with the dairy industry’s strict hygiene requirements. Moreover, the existing installation did not guarantee accurate dosing or effective dust containment, which consequently led to health risks and productivity losses. In light of these constraints, the manufacturer was looking for an automated packaging line that was both flexible and fully integrable within the physical constraints of the factory. In addition, the solution had to guarantee hygiene, operator safety and regulatory compliance for sensitive products such as lactose and whey. Finally, the customer aimed to strengthen in-line quality control by integrating automatic detection and rejection devices.

Customer objectives

- Achieve a rate of 300 bags/hour.

- Ensure high dosing accuracy for sensitive products.

- Ensure a strictly hygienic environment with CIP/DIP.

- Achieve effective dust containment during packaging.

- Integrate a hermetic bag sealing system.

- Adapt to the physical and dimensional constraints of the factory.

- Add automatic quality control devices (weight, metal).

Customer product

Milk powder

Milk powder is dehydrated milk from which water has been removed to ensure long-term, stable preservation. It is used in the food industry to manufacture dairy products, pastries, chocolates, infant nutrition products and industrial formulations requiring a stable, easy-to-measure dairy ingredient.

The solution provided

Palamatic Process has designed a complete high-speed bagging line based on the HBM 1040 bagging machine. The solution incorporates precise dosing, bottom-up filling, optimised deaeration and FTS hermetic sealing. It also includes automated quality control, centralised suction and overall control via HMI.

The solution implemented includes:

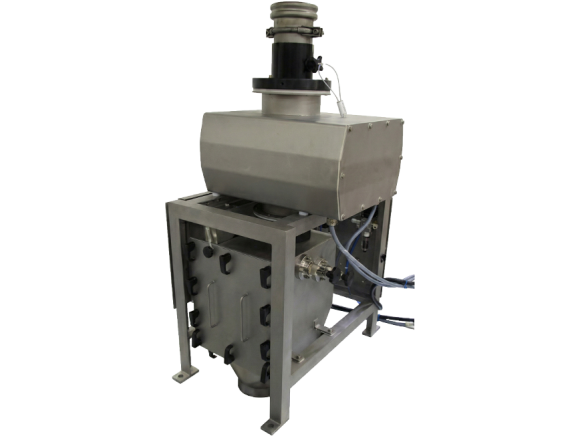

- HBM 1040 automatic bagging machine

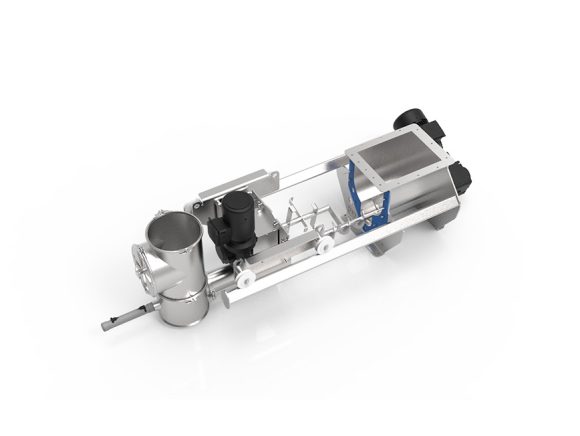

- Vertical screw feeder with 400 L hopper

- Fine-dosing screw (optional)

- Porous deaeration lances

- FTS system for preparing and sealing the bag opening

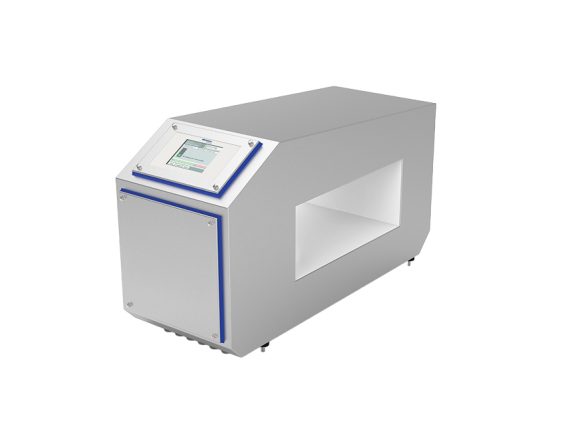

- Checkweigher with automatic rejection

- 650 m³/h centralised suction system

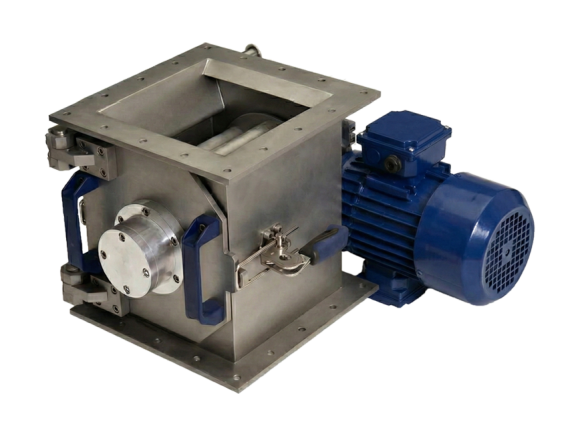

- Metal detector

- 316L in-line sampler

- Removable 316L feed screw

- Robotic bag transfer arms

- Height-adjustable conveyors

Results obtained

| Client objectives | Preliminary design (estimated) | Post-project (completed) |

|---|---|---|

| Achieve 300 bags per hour | 120–150 bags per hour | 300–400 bags per hour |

| Improve dosing accuracy | ±50 to ±80 g difference | ±10 g thanks to the vertical dispenser |

| Ensure perfect hygiene | Manual cleaning, partial | Hygiene controlled via CIP/SIP |

| Limit dust | Significant emissions | Aspiration 650 m³/h + bottom-up |

| Airtight closure of bags | Irregular weld | Waterproof and compliant FTS |

| Automating quality control | Manual checks, possible errors | Checkweigher & metal detector |

| Adapting to the building | Rigid, non-flexible implementation | Compact modules, adapted to the layout |

Benefits for the customer

- High production rate of up to 400 bags/hour.

- Highly accurate dosing with a tolerance of ±10 g.

- Enhanced hygiene and effective dust containment.

- Automated quality control: dynamic weighing and metal detection.

- Hermetic sealing of bags, ensuring product compliance.

Products handled

The Palamatic Process automated bagging line is designed for packaging sensitive milk powders, while ensuring dosing accuracy, hygiene and dust containment.

- Lactose

- Milk powder

- Whey

- Sensitive and formulated milk powders

- Light powders (density 400 to 770 kg/m³)

- Powdered products requiring high containment

- Powders packaged in paper, PE or PP bags

A unique HALPAQ × Palamatic synergy

To meet these requirements, Palamatic Process designed and delivered a complete solution combining HALPAQ technologies and process integration expertise:

The equipment used for this project

Equipment

Do you have a similar project ?

Are you looking to design a hygienic, automated and compact packaging line

for your food, nutraceutical or animal feed powders ?